Main feature:

¡·Modular structure design which is easy for adjustment. Machine function upgrade is available based on customer request.

¡·Machine drive is controlled by independent motor.

¡·Special sheet correction device ensures accuracy sheet feeding.

¡·Strengthened and widen belts which is suitable for corrugated box.

¡·Machine guide plate equipped with electric movement system which is easy for adjustment.

¡·Upper and lower plate adopts linear guiding system, which ensures mechanical accuracy of movement.

¡·Humanized design of accessories installation, simple and easy to operate.

¡·Whole machine can be adjusted by one hexagonal wrench.

¡·Trombone (pressing)unit equipped with correction and alignment device,which improves gluing effect.

¡· Collection unit adopts cylinder pressure system, which helps to adjust pressure and ensures product gluing effect. User friendly touch screen control panel.

¡·The remote controller makes machine operation more convenient.

Performance Specifications:

|

Model

|

JH-1200P

|

JH-1450

|

JH-1700

|

JH-2100

|

JH-2300

|

JH-2800

|

JH-3200

|

|

MAX.SHEET SIZE

|

1200¡Á1300mm

|

1450¡Á1300mm

|

1700¡Á1300mm

|

2100¡Á1300mm

|

2300¡Á1300mm

|

2800¡Á1300mm

|

3200¡Á1300mm

|

|

MIN.SHEET SIZE

|

420¡Á180mm

|

420¡Á180mm

|

420¡Á180mm

|

520¡Á180mm

|

520¡Á180mm

|

520¡Á180mm

|

520¡Á180mm

|

|

APPLICABIE PAPER

|

Cardboard:300g,corrugated paper F¡¢E,¡¢C,¡¢B¡¢A,¡¢EB,¡¢AB

|

|

MAX.BEIT SPEED

|

250M/min

|

250M/min

|

250M/min

|

250M/min

|

250M/min

|

250M/min

|

250M/min

|

|

MACHINE LENGTH

|

23000mm

|

23000mm

|

23000mm

|

23000mm

|

23000mm

|

23000mm

|

23000mm

|

|

MACHINEWIDTH

|

2400mm

|

2700mm

|

2900mm

|

3400mm

|

3600mm

|

4200mm

|

4800mm

|

|

MACHINE HEIGHT

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

|

TOAI POWER

|

42KW

|

42KW

|

45KW

|

45KW

|

45KW

|

45KW

|

60KW

|

|

MAX.AIR DISPLACEMENT

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

0.7m3/min

|

|

TOTAL WEIGHT

|

15000kg

|

15500kg

|

16000kg

|

16500kg

|

17000kg

|

18000kg

|

20000kg

|

AC = Standard folding boxes , double-wall boxes and bottom lock boxes.

PC=Standard folding boxes , double-wall boxes and bottom lock boxes.

PCW=Standard folding boxes , double-wall boxes , bottom lock boxes and 4/6 corner boxes.

Specific auxiliaries can produce special boxes like CD boxes , ladder-shaped boxes , box-in-boxes , 3-fold silk stocking boxes.

This catalogue is for general reference only and special design is available.

Jinghong Packaging Machinery Co ., Ltd . reserves the final interpretation right of the above information.

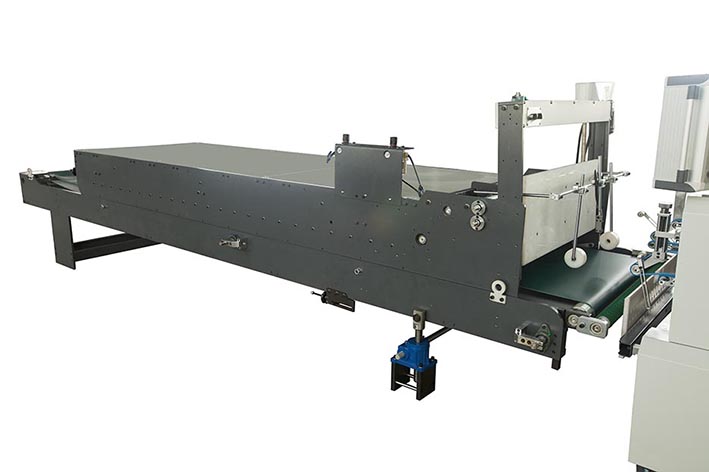

Functional composition£º

Feeding unit

Sheet feeding is driven by independent motor. The vacuum suction belt ensures the accuracy and stability of sheet conveying.

Sheet correction unit

Auto-correction unit ensures feeding accuracy Adjustable upper pressing drive is suitable for different thickness sheet.

Bottom lock and 4/6 corner system

Specially designed 4/6 corner system, which is driven by high-precision servo control system. Thus realizes special folding functions such as bottom, front lock and 4/6 corner, which can meet the functions of various covers and 4/ 6 corner boxes.

Folding unit

Unique elongated folding module enables the cardboard to be stretched into shape.The speed of the left and right conveyor belts can be adjusted separately, which ensures straight conveying by correcting the box.

Trombone (pressing) unit

Adjustable upper and lower belts, works together with correction device and jamming detecting device.

Conveying unit

Correction positioning before conveying unit, helps to avoid from improper gluing.