Main features:

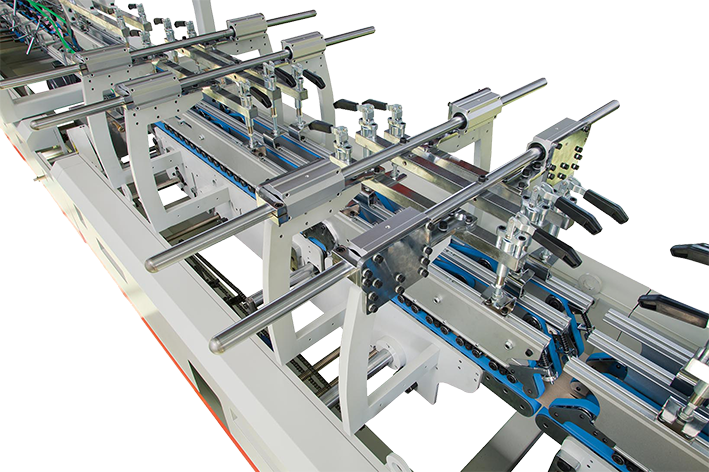

¡·Modular structure design which is easy for adjustment. Machine function upgrade is available based on customer request.

¡·Humanized design of accessories installation, simple and easy to operate.

¡·Special sheet correction device ensures accuracy sheet feeding.

¡·Specific design ensures 180 degree on 1st crease and 3rd crease which makes the box easier to be extended.

¡· Segmental speed wave device.

¡·User friendly touch screen control panel.

¡·High speed electronic kickboard counter.

¡·Collection unit adopts cylinder pressure system, which helps to adjust pressure and ensures product gluing effect.

¡·The remote controller makes machine operation more convenient.

¡·Equipped with printing inspection unit, barcode inspection unit and gluing inspection unit.

¡·Intelligent one button modeling system, superior to general visual inspection, adopts imported components and high-tech image processing system to achieve automatic feeding, inspection, finished / waste classification, product quality analysis, etc.

Performance specifications:

|

Model

|

JH650-J

|

JH850-J

|

JH1100-J

|

|

MAX.SHEET SIZE

|

650¡Á700mm

|

850¡Á900mm

|

1100¡Á900mm

|

|

MIN.SHEET SIZE

|

120¡Á70mm

|

125¡Á70mm

|

130¡Á70mm

|

|

APPLICABIE PAPER

|

Cardboard:250g-800g,corrugated paperF,¡¢E

|

|

Printing image accuracy

|

0.16MM¡Á0.15MM

|

|

Embossing image accuracy

|

0.08MM¡Á0.125MM

|

|

Barcode image accuracy

|

0.05MM¡Á0.05MM

|

|

Regular printing unit image accuracy

|

0.16MM¡Á0.15MM

|

|

Max. inspection width

|

650MM

|

|

Min. dot size

|

0.1MM2(¸ß¶ÈŒ¦±È)/0.3MM2(Ò»°ãŒ¦±È)

|

|

Color difference

|

×Ô„ÓŒ¦±È¡÷E¡Ý3Nbs

|

|

Max.inspection speed

|

250M/min

|

|

MAX.BEIT SPEED

|

450M/min

|

450M/min

|

450M/min

|

|

MACHINE LENGTH

|

21000mm

|

21000mm

|

21000mm

|

|

MACHINE WIDTH

|

1350mm

|

1500mm

|

1800mm

|

|

MACHINE HEIGHT

|

1450mm

|

1450mm

|

1450mm

|

|

TOAI POWER

|

33.5KW

|

33.5KW

|

33.5KW

|

|

MAX.AIR DISPLACEMENT

|

1m3/min

|

1m3/min

|

1m3/min

|

|

TOTAL WEIGHT

|

6500kg

|

7000kg

|

8500kg

|

AC = Standard folding boxes , double-wall boxes and bottom lock boxes.

PC=Standard folding boxes , double-wall boxes and bottom lock boxes.

PCW=Standard folding boxes , double-wall boxes , bottom lock boxes and 4/6 corner boxes.

Specific auxiliaries can produce special boxes like CD boxes , ladder-shaped boxes , box-in-boxes , 3-fold silk stocking boxes.

This catalogue is for general reference only and special design is available.

Jinghong Packaging Machinery Co ., Ltd . reserves the final interpretation right of the above information.

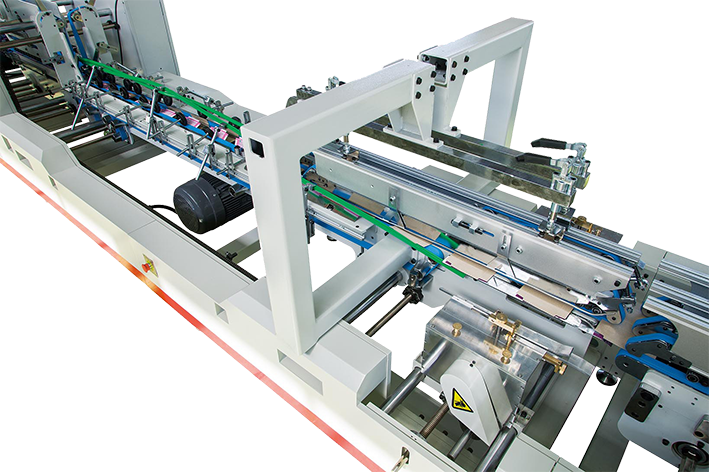

Functional composition:

Feedingun

Sheet feeding is driven by independent motor.The ubraten bet ne eoe suctoe bett emue be aconacy and stbidy of sheet canveyng.

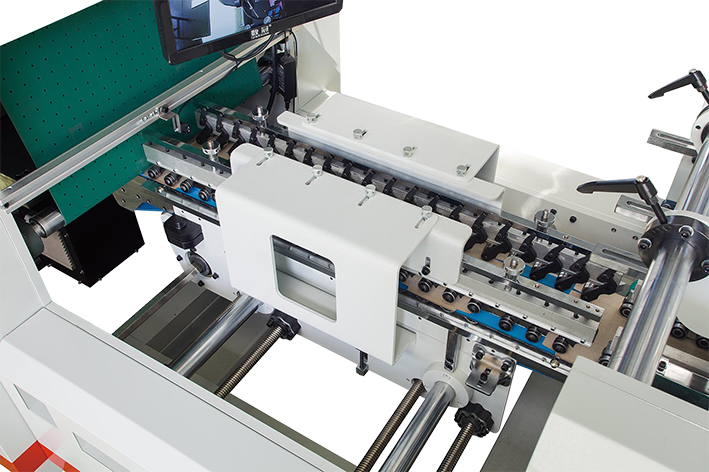

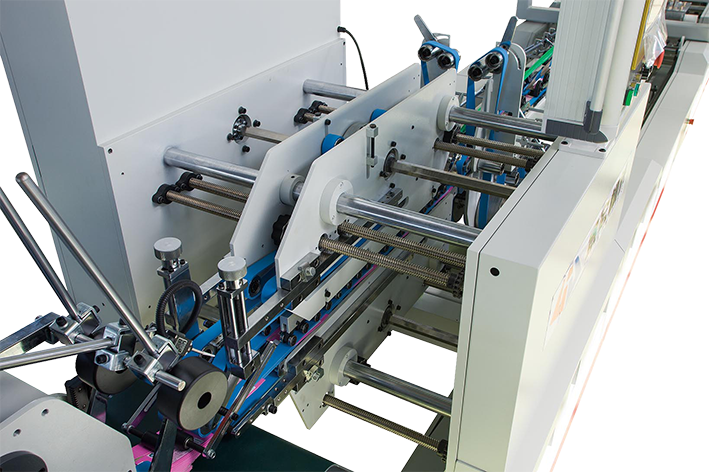

Sheet correction unit

Auto-correction unit ensures feeding accuracy. Adjustable upper pressing drive is suitable for different thickness sheet.

Inspection unit£º

Equipped with strong suction device to ensure accurate detection of paper.

Waste rejection unit£º

Equipped with high precision sensor to kick out waste products accurately.

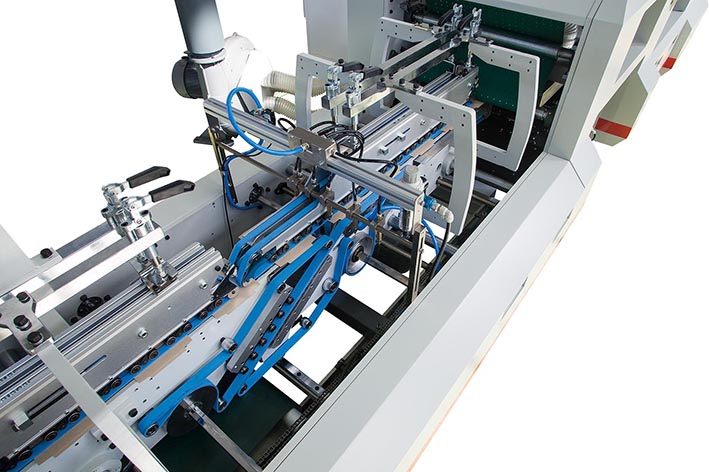

Pre-folding section

Specific design ensures 180 degree on 1st crease and 165 degree on 3rd crease which makes the box easier to be extended.

Speed wave unit

Specially designed device to realize speed wave of 1-3 bottom lock.

Specially designed device to realize speed wave of 2-4 bottom lock.

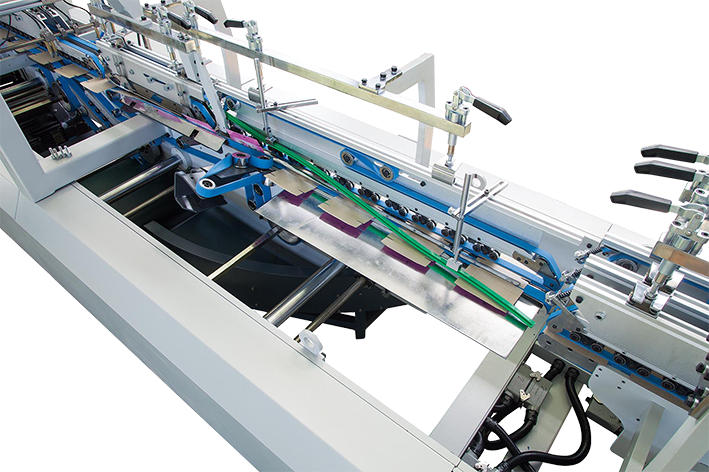

FOLDING

2nd crease 180 degree,4th crease 180 degree Specifically designed to adjust belt feeding speed separately to correct box embryo running directior and ensure straight feeding.

TROMBONE(PRESSING)

Auto-collecting of paper/sheets and water spray by photoelectric counter.

Paper-jam inspection device

Adjustable upper and lower belts for easy and simple operation.

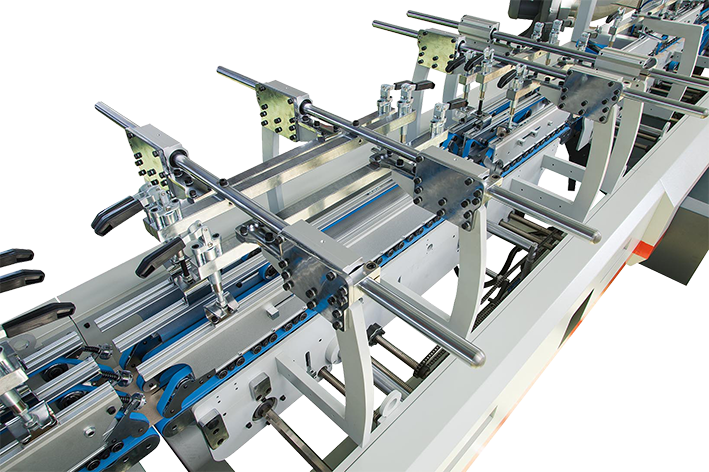

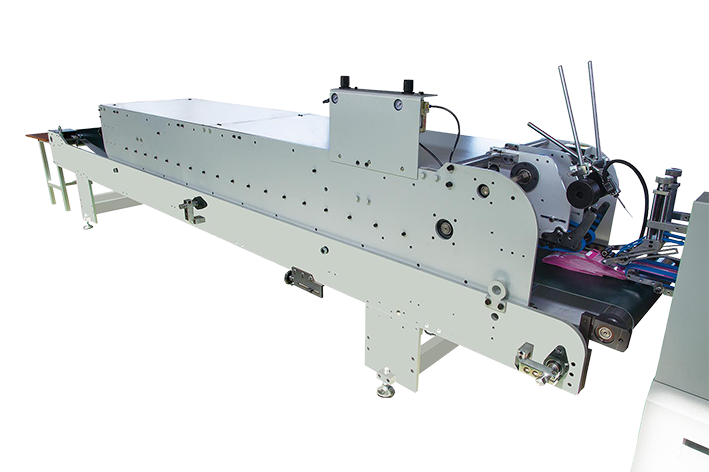

Press convey section£º

Movable stacking belts of 2 boards on left and right, adjustable in on-line production per stacking requirement of the boxes to improve efficiency.

Special and extra sponge belts for pressing of concave part the boxes piles.

|