Main features:

¡·Modular structure design which is easy for adjustment. Machine function upgrade is available based on customer request.

¡·Machine drive is controlled by independent motor.

¡·Special sheet correction device ensures accuracy sheet feeding.

¡·Strengthened and widen belts which is suitable for corrugated box.

¡·Machine guide plate equipped with electric movement system which is easy for adjustment.

¡·Upper and lower plate adopts linear guiding system, which ensures mechanical accuracy of movement .

¡·Humanized design of accessories installation, simple and easy to operate.

¡·Whole machine can be adjusted by one hexagonal wrench.

¡·Trombone(pressing) unit equipped with correction and alignment device,which improves gluing effect.

¡·Collection unit adopts cylinder pressure system, which helps to adjust pressure and ensures product gluing effect.

¡·User friendly touch screen control panel.

¡·The remote controller makes machine operation more convenient.

Performance specifications:

|

Model

|

JH-1700P

|

JH-1900

|

JH-2400P

|

JH-2800P

|

JH-3200P

|

|

MAX.SHEET SIZE

|

850¡Á1400mm

|

950¡Á1400mm

|

1200¡Á1400mm

|

1400¡Á1400mm

|

1600¡Á1400mm

|

|

MIN.SHEET SIZE

|

520¡Á320mm

|

520¡Á320mm

|

520¡Á320mm

|

520¡Á320mm

|

520¡Á320mm

|

|

APPLICABIE PAPER

|

corrugated paper E,¡¢C¡¢B¡¢A,¡¢AB

|

|

MAX.BEIT SPEED

|

120M/min

|

120M/min

|

120M/min

|

120M/min

|

120M/min

|

|

MACHINE LENGTH

|

18000mm

|

18000mm

|

18000mm

|

18000mm

|

18000mm

|

|

MACHINEWIDTH

|

2450mm

|

2650mm

|

3150mm

|

3650mm

|

3950mm

|

|

MACHINE HEIGHT

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

2000mm

|

|

TOAI POWER

|

45KW

|

45KW

|

45KW

|

45KW

|

60KW

|

|

MAX.AIR DISPLACEMENT

|

1.7m3/min

|

1.7m3/min

|

1.7m3/min

|

1.7m3/min

|

1.7m3/min

|

|

TOTAL WEIGHT

|

16000kg

|

16000kg

|

16500kg

|

17500kg

|

19500kg

|

This catalogue is for general reference only and special design is available.

Jinghong Packaging Machinery Co ., Ltd . reserves the final interpretation right of the above information.

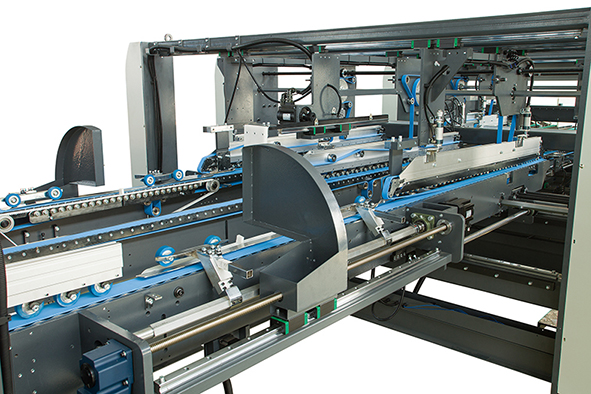

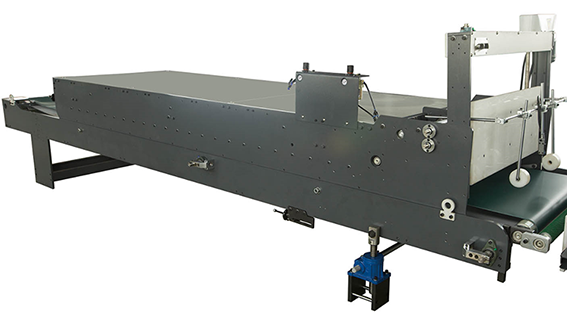

Functional composition:

Feeding unit

Dual servo synchronous paper feeding system

With vacuum suction tape, ensuring accurate and stable paper feeding.

Splicing component

Four sets of cylinder paper-stopper positioning system, ensuring the high bottom line precision of the carton.

Two sets of pneumatic side positioning system at left and right side,ensuring the precision at the joint of the carton.

Dynamic feeding splicing of two pieces under the control of PLC and machine interface,ensuring the precision of splicing.

Folding unit

A pair of servo motors at the left and right side simulating the manual dynamic folding, with the push-back servo motor to prevent high-low lines and scissors crossing in the rebounding process of paper after the formation,so as to reduce the defective products to a great extent.

Trombone (pressing)unit

Adjustable upper and lower belts, works together with correction device and jamming detecting device.

Conveying unit

Correction positioning before conveying unit, helps to avoid from improper gluing.

|